ATS Formwork Plywood

ATS is leading formwork plywood supplier for leading formwork and construction companies in Australia, Europe, Middle East and rest of the Asia pacific.Availability in India C&F basis only.

With recent GR (Feb 2025) form central government of India for all types of imported plywood including formwork plywood BIS (Bureau of Indian Standards) approval is mandatory. As per IS 5539:1969, plywood must undergo preservative treatment using ACC, CCA, or CCB via a vacuum-pressure process, with a minimum preservative retention of 12 kg/m, this preservative treatment to enhance plywood durability against decay, insects, and environmental factors.

Requested preservative treatment will increase the process cost tremendously and could not be justify for Indian market.

ATS formwork plywood adhere the global perspectives, countries such as the USA, EU, and Australia, formwork plywood (e.g., Southern Pine, Birch) is often treated with minimal preservatives (1.6-3.4 kg/m³ per AWPA standards) or relies on phenolic coatings instead of heavy chemical impregnation.

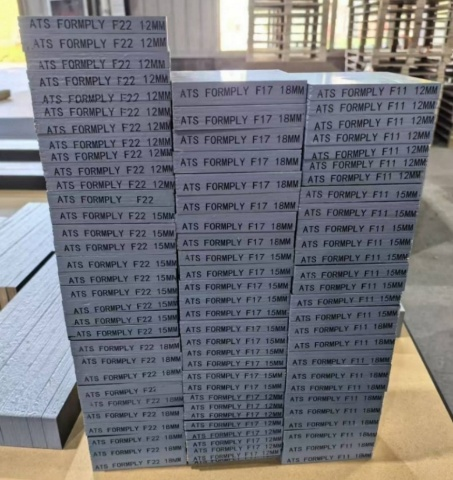

Below are our some of our products (please share this text line)

Similar or better-quality results like plywood available in options, as Vietnam and Russian made.

- Sizes: 2440 x 1220, 2400x1200mm, 1800x1200mm

- Thickness: 9, 12, 15, 17, 18mm

- Stress Grade F11: AS 6669 : 2016, Bending Strength ≥ 31Mpa, Shear Strength ≥ 4.5Mpa, Modulus of Elasticity ≥ 10500Mpa

- Both faces Finish: 165g/m2 Dynea phenolic resin black film

- Concrete surface finish: Class 2 in compliance with AS 6669 - 2016 (Architectural fair-faced concrete surface finish)

- Face Veneer: "B " grade hardwood veneer

- Back Veneer: "B " grade hardwood veneer

- Inner Plies: "C & Better" hardwood veneer

- Resin: Phenolic Exterior Glue with A-Bond quality, E0 Formaldehyde Emission.

- High number of re-uses : The number of re-uses depends on the factors like,

- the glue used in the production of panels

- the requirement of concrete surface finish of individual jobsite

- the treatment of the panel in the jobsite

- the maintenance of the panel in practice etc.,

- 25 ~ 35 times or even more

- Moisture content: Moisture Content range 8 - 12%

- Edge Seal: Edge sealed with grey water-proofing paint

- Working Face: 2 working faces (G2S)

- Stamp: BSI Bench Mark

Similar or better-quality results like plywood available in options, as Korian made ply.

- Sizes: 2440 x 1220, 2400x1200mm, 1800x1200mm

- Thickness: 9, 12, 15, 17, 18mm

- Stress Grade F17: AS 6669 : 2016, Bending Strength ≥ 45Mpa, Shear Strength ≥ 5.1Mpa, Modulus of Elasticity ≥ 14000Mpa

- Both faces Finish: 165g/m2 Dynea phenolic resin black film

- Concrete surface finish: Class 2 in compliance with AS 6669 - 2016 (Architectural fair-faced concrete surface finish)

- Face Veneer: "B " grade hardwood veneer

- Back Veneer: "B " grade hardwood veneer

- Inner Plies: "C & Better" hardwood veneer

- Resin: Phenolic Exterior Glue with A-Bond quality, E0 Formaldehyde Emission.

- High number of re-uses : The number of re-uses depends on the factors like,

- the glue used in the production of panels

- the requirement of concrete surface finish of individual jobsite

- the treatment of the panel in the jobsite

- the maintenance of the panel in practice etc.,

- 25 ~ 35 times or even more

- Moisture content: Moisture Content range 8 - 12%

- Edge Seal: Edge sealed with grey water-proofing paint

- Working Face: 2 working faces (G2S)

- Stamp: BSI Bench Mark

Similar or better-quality results like plywood available in options, as Birch formwork plywood.

- Sizes: 2440 x 1220, 2400x1200mm, 1800x1200mm

- Thickness: 9, 12, 15, 17, 18mm

- Stress Grade F22: AS 6669 : 2016, Bending Strength ≥ 60Mpa, Shear Strength ≥ 5.5Mpa, Modulus of Elasticity ≥ 16000Mpa

- Both faces Finish: 165g/m2 Dynea phenolic resin black film

- Concrete surface finish: Class 2 in compliance with AS 6669 - 2016 (Architectural fair-faced concrete surface finish)

- Face Veneer: "B " grade hardwood veneer

- Back Veneer: "B " grade hardwood veneer

- Inner Plies: "C & Better" hardwood veneer

- Resin: Phenolic Exterior Glue with A-Bond quality, E0 Formaldehyde Emission.

- High number of re-uses : The number of re-uses depends on the factors like,

- the glue used in the production of panels

- the requirement of concrete surface finish of individual jobsite

- the treatment of the panel in the jobsite

- the maintenance of the panel in practice etc.,

- 25 ~ 35 times or even more

- Moisture content: Moisture Content range 8 - 12%

- Edge Seal: Edge sealed with grey water-proofing paint

- Working Face: 2 working faces (G2S)

- Stamp: BSI Bench Mark